----Wu Yufen, general manager of Tianyi technology, visited many domestic enterprises

Under the common goal of global carbon neutrality, the market scale of pulp molding packaging products is growing rapidly, and the design and updating of pulp molding equipment are also changing with each passing day. As a professional manufacturer of high temperature resistant and thermal insulation materials, from October 6, 2021, general manager Wu Yufen and marketing director Zhang Jianbo jointly visited many leading pulp molding equipment and products enterprises in Guangdong. For more than 20 days, they had detailed communication and on-site analysis with the chairman, general manager and professional technicians of many enterprises.

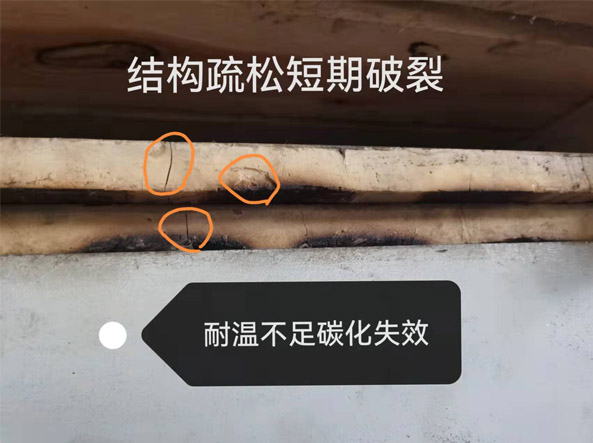

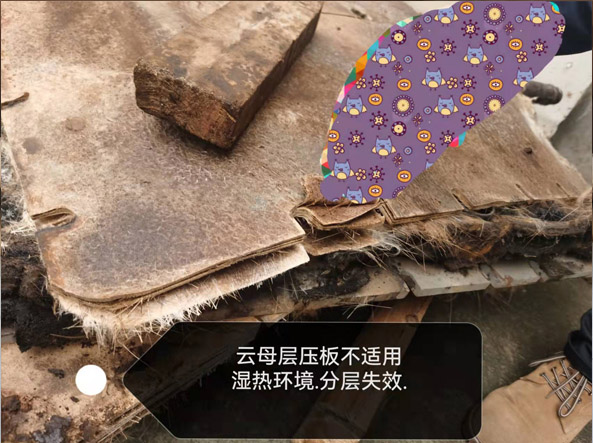

In the communication with pulp molded products manufacturers, it is found that most of the products factories suffer from the sequelae of "high temperature disease" and high energy consumption expenditure. The mold temperature is 200-250 ℃, and some shutdown temperatures are as high as 270 ℃. At the same time, due to the mismatch between the temperature resistance and thermal insulation performance of thermal insulation materials and the humid and hot environment, the mold high temperature continues to overflow and drain, resulting in a variety of adverse consequences: First, the enterprise's natural gas or electricity charges remain high, and the competitive cost is difficult to control; Second, the core components of the equipment are affected by high temperature for a long time and damaged for a short time; Third, the mold heat insulation boards configured by the upstream equipment manufacturers do not match, which is not suitable for the high-temperature, humid and hot water vapor environment. In a short time, they are greatly deformed, roughened and extruded, carbonized and layered, resulting in inaccurate mold pressing and inaccurate product molding, especially the qualified rate of industrial exquisite packaging products; Fourth, the continuous high temperature in the workshop environment has exceeded the human body's tolerance for a long time, resulting in employees' physical discomfort and frequent flow. The chairman and general manager of several product enterprises personally paid attention to the selection of thermal insulation materials and poured out all kinds of confusion.

In their communication with pulp molding equipment manufacturers, they also feel the urgency of self upgrading of thermal insulation materials. Several leading enterprises attach great importance to the functional indicators of thermal insulation materials in equipment design, and try to equip end customers with good materials that can save energy, reduce consumption, promote yield, environmental protection and durability, It is recognized that the use of inferior thermal insulation materials will become an important factor affecting the market competitiveness of equipment enterprises. However, due to factors such as professional identification of materials or lack of understanding of high-quality channels, there are situations such as searching everywhere on the Internet, buying low-quality products at a low price, buying low-quality products at a high price, and directly buying high-priced foreign products for important orders. Basically, N kinds of bad materials can be evaluated after trial, and there is a lack of stable and reliable thermal insulation material suppliers. Therefore, they are deeply confused and seek a breakthrough.

In pulp molding equipment, thermal insulation materials are indispensable for the thermal insulation of molds and play a key role in saving energy by about 20%. Since 2020, especially after the energy shortage is controlled, product enterprises in Guangdong, Fujian and Zhejiang have begun to replace high-quality thermal insulation boards by themselves, realizing effective energy conservation, It also forces equipment manufacturers to actively look for excellent cost-effective thermal insulation materials to meet the needs of market competition.

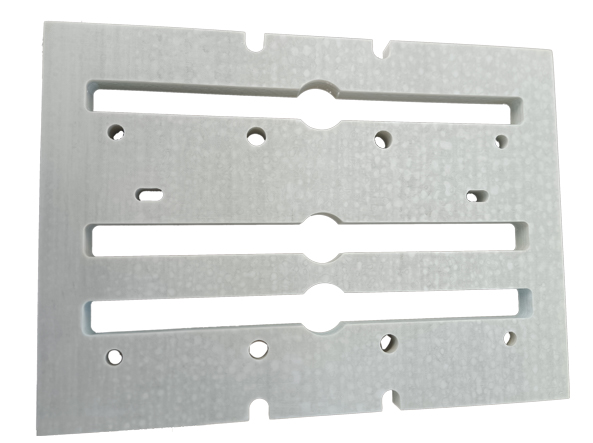

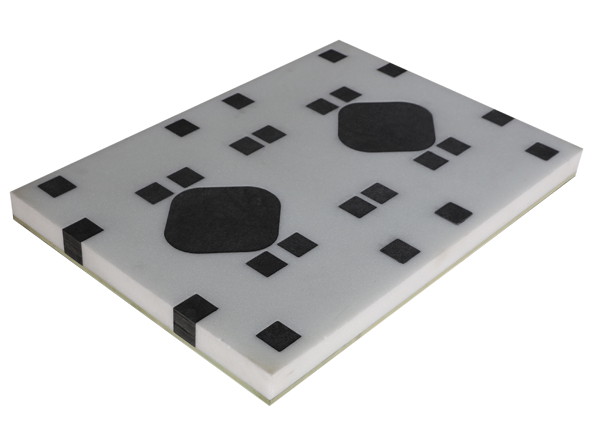

Tianyi technology is based on high temperature resistant polyimide resin (PI) core technology, which has been committed to the R & D and manufacturing of high-temperature insulation materials for more than ten years, has the advantages of professional product design, and has formed a series of more than 20 varieties of thermal insulation materials, including special thermal insulation materials for upper and lower compression of pulp molding equipment in humid and hot environment, special thermal insulation materials for side, special thermal insulation materials for transfer mesh frame, etc., which can solve the problems of equipment in an all-round way Thermal insulation. During this visit, many orders for thermal insulation materials were also received.

According to the customer's design drawings and files, Tianyi technology can quickly and efficiently provide finished product processing materials for direct installation and use, provide measured data compared with that before replacement, and assist customers in field testing and comparison results.